5 Axis Machining

“5 Axis machining” refers to a CNC machine’s capabilities to move a part or a tool on five different CNC axes at the same time.

The tool is able to move the part in two directions (first two axes – ‘X and Y’), and the tool moves up and down (third axis – ‘Z’). The tool can rotate on two additional rotary axes (axes four and five – ‘A and B’) which help the cutting tool approach the part from all directions. 5-axis CNC machining is quick and efficient, offering a “one and done” approach.

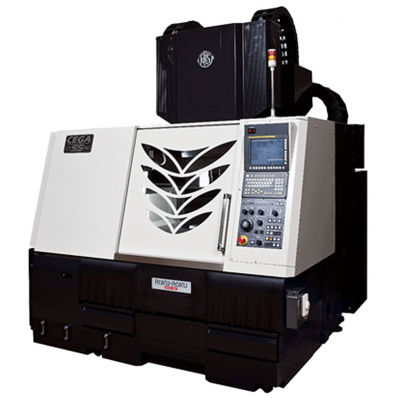

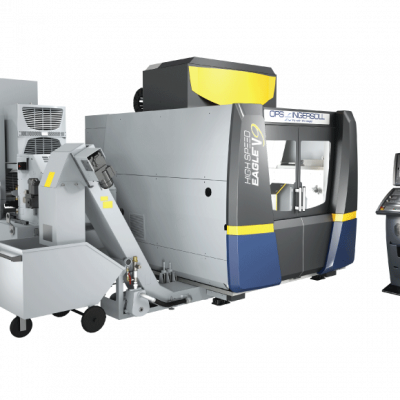

As a leading and trusted authorized distributor for brands like Mitsubishi and Roku-Roku Sangyo, we’re committed to supplying customers with 5-Axis machining centers that afford a wide range of automation is available to ensure highest machine availability and spindle utilization. Additionally, these units are of an economical size – maximize your operation’s floor space and productivity!

Showing all 5 results